Separate Fixed Calorimeter

- Introduction

- Picture

- Specification

- Download

- Installation Video

- Inquiry

Name:Separate Fixed Calorimeter

Model:LRF-2000S-R

General Introduction:

LRF-2000S-R is wall-mount economical ultrasonic heat/cold meter. It is comprised of wall-mount ultrasonic flow meter and a pair of temperature sensors PT100

Features:

High Accuracy measuring

Linearity: better than 0.5%, Repeatability: better than 0.2%, Accuracy: better than ±1%

Wide measuring range

Several types transducer for selection, measuring pipe size from DN32mm to DN6000mm

High Reliability

Adopt low voltage, multi-pulse technology to improve accuracy, useful life and reliability

Strong Anti-interference

Dual-balance signal differential receiver/driver circuit to avoid interference of converter,TV ower, high voltage line etc.

Powerful Recording Function

Automatically record the following data:

1.The totalizer data of the last 512 days/128 months/10 years

2.The time and corresponding flow rate of the last 64 times of power on and off events

3. The working status of the last 32 days

With the clamp on ultrasonic temperature transducer

Optional transducer :

Optional Temperature Transducer:

Optional Main unit:

| Types | Picture | Spec. | Model | Measurement Range | Temperature | Accuracy |

| Clamp on |   |

Small Size | TS-2 | DN32~DN100 | -30~90℃ |

Better than ±1% |

|

Medium Size | TM-1 | DN50~DN700 | |||

|

Large Size | TL-1 | DN300~DN6000 | |||

| High Temperature Clamp on |

|

Small Size | TS-2-HT | DN32~DN100 | -30~160℃ | |

|

Medium Size | TM-1-HT | DN50~DN700 | |||

| Insertion |   |

Standard | TC-1 | DN80~DN6000 | -30~90℃ |

Better than ±1% |

|

Lengthen | TC-2 | DN80~DN6000 | |||

| Prover Section | Standard | G1 | DN15 -1000mm

(see appendix 2)

|

-30C ° ∼ 90C ° |

Better than ±0.5% |

|

| Power Supply | DC8-36V or AC220V | |||||

| Input | 3 channel 4-20mA analog input | |||||

| Output |

Isolation RS-232/RS-485 output, 2 channel isolation OCT

output: 1 channel isolation 4-20mA output (two-wire system)

|

|||||

| Communication Protocols |

Compatible with METER-BUS, MODBUS, Fuji extended protocol and general water meter protocol

|

|||||

Optional Temperature Transducer:

|

Clamp on temperature transducer PT100 | No need to cut off water, no pressure loss |

|

Insertion temperature transducer PT100 | Need to cut off water, no pressure loss |

Optional Main unit:

| Wall-mount | Panel-mount | Explosion-proof |

|

|

|

| Wall mounted LRF-2000SW Indoor or instrument box installation Dimension:170*180*56mm Power supply:DC8~36V or AC85~264V |

Panel mounted LRF-2000SS Instrument Cabinet installation Dimension:170*180*56mm Hole-opening dimension:156*76mm Power supply:DC8~36V or AC85~264V |

Explosin-proof LRF-2000SD Explosin-proof installation Dimension :298*298*110mm Power supply:DC 8~36V or AC85~264V |

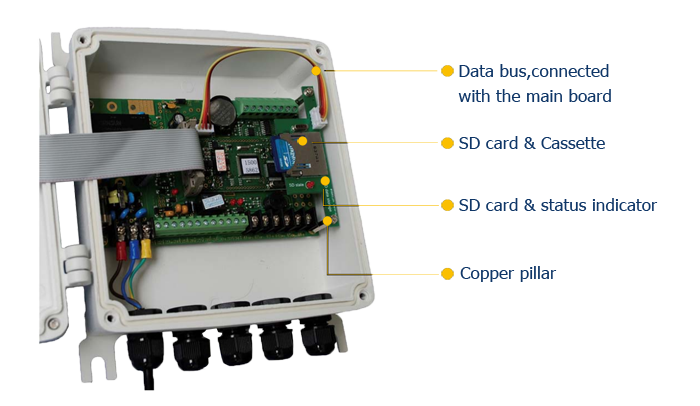

Transmitter:

The physical details of the plan:

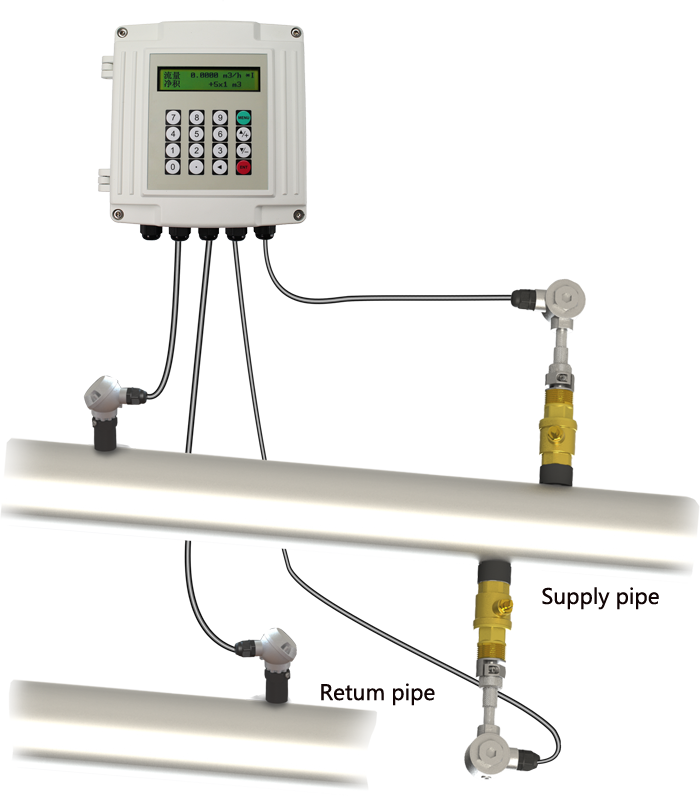

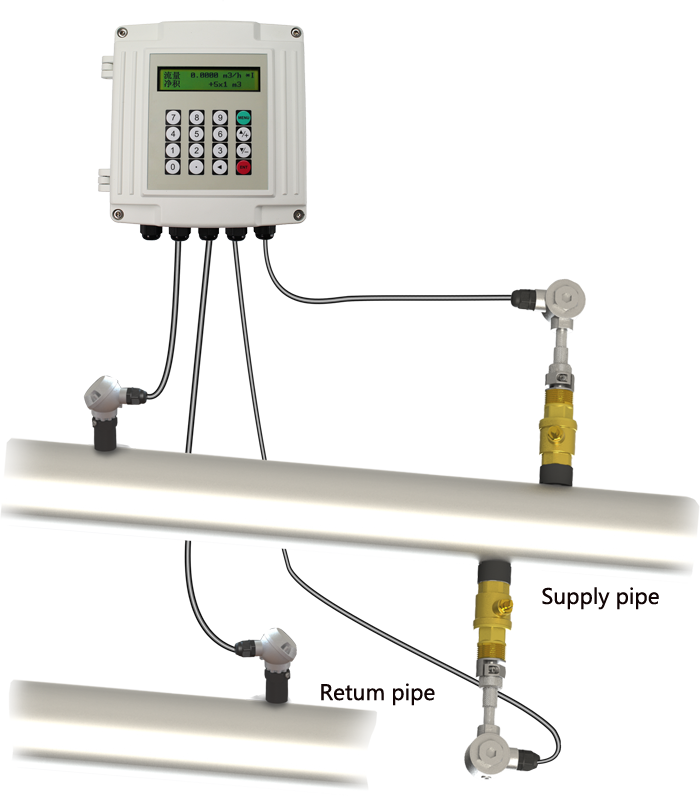

Installation diagram:

Structure of clamp-on measuring

Structure of insertion measuring

Structure of clamp-on measuring

Structure of insertion measuring

Structure of Prover Section measuring

| Item | Performance and Parameter | |

| Convertor | Principle | transit-time ultrasonic flowmeter |

| Accuracy | Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2% | |

| Display | 2×20 character LCD with backlight, support the language of Chinese, English and Italy Convertor dimension:170*180*56cm | |

| Operation | Support 16 key light touch keyboard and the Simulation keyboard software | |

| Signal Output | 1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1% | |

| 1 way OCT pulse output( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms) | ||

| 1 way Relay output | ||

| Signal Input | 3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level | |

| Connect the temperature transducer Pt100, can finish the heat/energy measurement | ||

| Data interface | Insulate RS485 serial interface, upgrade the flow meter software by computer, support the MODBUS, METER-BUS etc. | |

| Other Function | Automatically remember the previous flow/energy data of 512 days, 128 months and 10 years | |

| Automatically remember the previous flow/energy data of 512 days working condition and check it | ||

| Automatically remember the previous 32 times power on/off time and flow rate | ||

| Special Cable | Twisted-pair cable, generally, the length under 50 meters; Select the RS485 communication. The transmission distance can over 1000m. | |

| Pipe Condition | Pipe Material | Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

| Pipe Diameter | DN32mm---6000mm | |

| Straight length pipe | Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. | |

| Measuring Medium | Type of Liquid | Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids |

| Temperature | Standard Transducer: -30--90℃; High-temperature transducer: -40--160℃ | |

| Turbidity | No more than 10000ppm and less bubble | |

| Flow rate | 0--±12 m/s | |

| Working Environment | Temperature | Main Unit: -20--60℃ |

| Flow transducer: -40--160℃; Temperature transducer: according to the customer’s demands. |

||

| Humidity | Main Unit: 85% RH; Flow Transducer: Ip67 | |

| Power Supply | DC 24V or AC 85-264V | |

| Power Consumption | 1.5W | |