- Metal Color Screen Ultrasonic Flow Meter

- Clamp-on Ultrasonic Flow Meter

- Insertion-type Ultrasonic Flow Meter

- Portable Ultrasonic Flow Meter

- Handheld Ultrasonic Flow Meter

- Handheld Ultrasonic Flow Meter

- Fixed-Clamp-on Ultrasonic Flow Meter

- Split-insertion-type Ultrasonic Flow Meter

- Ultrasonic Flow Module

Ultrasonic Flow Module

- Introduction

- Picture

- Specification

- Download

- Installation Video

- Inquiry

Name:Ultrasonic Flow Module/RTU

Model:LRF-2000M

General Introduction:

LRF-2000M, the ultrasonic flow module, is best choice for system integration or network measurement because of its small volume, light weight, easy operation, power function and lowest cost.

Features:

Powerful Functions

Current output: 4-20mA, one channel, can be used for flow/heat transmitter;

OCT output: two channel, can be used for flow / heat switch;

Current input: 4-20mA, three channel, can be used for data collector;

Tri-wire resistance signal input (PT100): two channel, can be used for calorimeter.

Far transmission distance

Connect flow/heat module and secondary meter through RS-485 interface, transmission distance up to 1000m .

Solve the problems of high cost of special cable, poor anti-interference, short transmission distance etc.

Wide measuring range

Several types transducer for selection, pipe size from DN 32mm to DN 6000mm

High Accuracy measuring

Accuracy: ±1%, linearity: 0.5%, repeatability: 0.2%

Optional transducer :

| Types | Picture | Spec. | Model | Measurement Range | Liquid Temperature | Accuracy |

| Clamp on |  |

Small Size | TS-2 | DN32~DN100 | -30~90℃ |

Flow±1% Heat±2% |

|

Medium Size | TM-1 | DN50~DN700 | -30~90℃ | ||

|

Large Size | TL-1 | DN300~DN6000 | -30~90℃ | ||

| High Temperature Clamp on |

|

Small Size | TS-2-HT | DN32~DN100 | -30~160℃ | |

|

Medium Size | TM-1-HT | DN300~DN1000 | -30~160℃ | ||

| Insertion |  |

Standard | TC-1 | DN80~DN6000 | -30~160℃ | |

|

Lengthen | TLC-2 | DN80~DN6000 | -30~160℃ | ||

| Prover Section |  |

Prover Section | G1 | DN15 -1000mm (see appendix 2) |

-30~160℃ | Flow±0.5% |

Transmitter:

size:

Measuring Diagram of flowmeter:

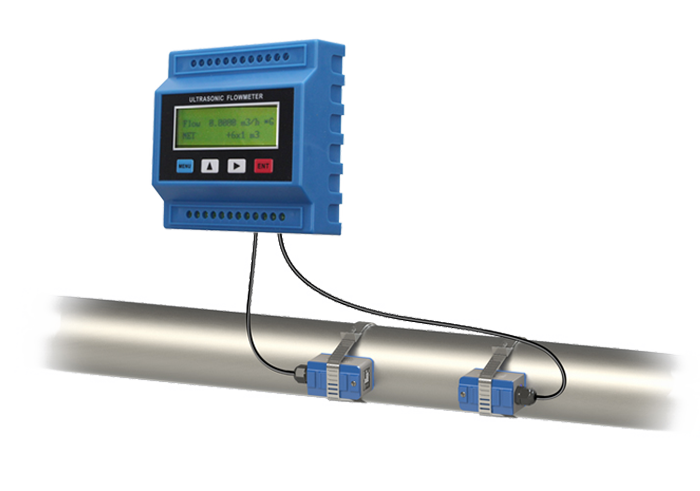

Clamp on:

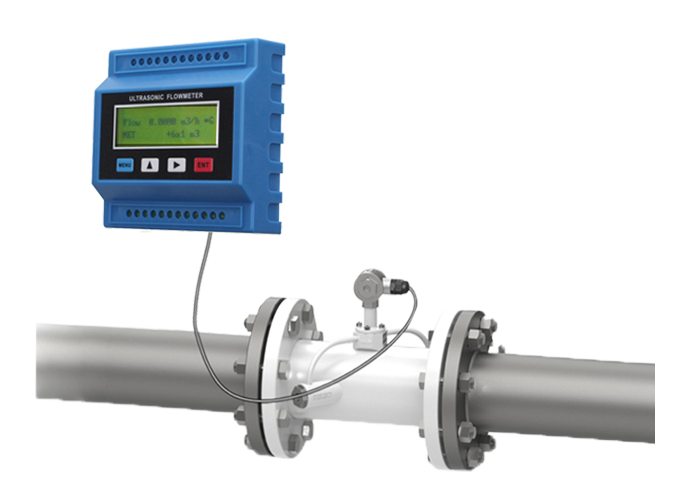

Insertion:

Pipe:

| Item | Performance and Parameter | |

| Convertor | Principle | transit-time ultrasonic flowmeter |

| Accuracy | Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2% | |

| Operation | 4 keyboards operation | |

| Signal Output | 1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1% | |

| 1 way OCT pulse output( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms) | ||

| 1 way Relay output | ||

| 3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level | ||

| Signal Input | Connect the temperature transducer Pt100, can finish the heat/energy measurement | |

| Data interface | Insulate RS485 serial interface, upgrade the flew meter software by computer, support the MODBUS, METER-BUS etc. | |

| Special Cable | Twisted-pair cable, generally, the length under 50 meters;Select the RS485 communication. The transmission distance can over 1000m. | |

| Pipe Condition | Pipe Material | Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

| Pipe Diameter | 32mm-6000mm | |

| Straight length pipe | Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. | |

| Measuring Medium | Type of Liquid | Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids |

| Temperature | Standard Transducer: -30--90℃; High-temperature transducer: -30--140℃ | |

| Turbidity | No more than 10000ppm and less bubble | |

| Flow rate | 0~±12 m/s | |

| Working Environment | Temperature | Main Unit: -20--60℃ |

| Humidity | Main Unit: 85% RH; Flow Transducer: Ip67 | |

| Power Supply | DC8~36V or AC10~30V | |

| Consumption | 1.5W | |