- Metal Color Screen Ultrasonic Flow Meter

- Clamp-on Ultrasonic Flow Meter

- Insertion-type Ultrasonic Flow Meter

- Portable Ultrasonic Flow Meter

- Handheld Ultrasonic Flow Meter

- Handheld Ultrasonic Flow Meter

- Fixed-Clamp-on Ultrasonic Flow Meter

- Split-insertion-type Ultrasonic Flow Meter

- Ultrasonic Flow Module

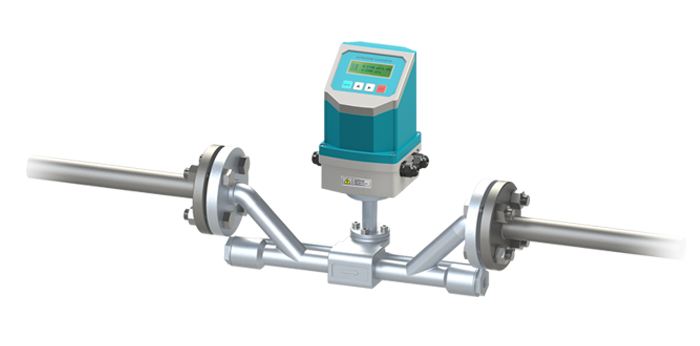

One-piece Tubular Ultrasonic Flow Meter

- Introduction

- Picture

- Specification

- Download

- Installation Video

- Inquiry

Name:One-piece Tubular Ultrasonic Flow Meter

General Introduction:

Model:LRF-2000F

General Introduction:

LRF-2000F ultrasonic flowmeter is to connect the motherboard with a 20-wire, 4-key parallel port keyboard display and package it into a sealed case. The online display and operation sensor can be divided into external clamp-type inserted tube segment, which has the advantages of high precision, wide range, no pressure loss and simple installation.

Features:

Working Conditions:

π type Pipe Transducer:

Flanged Connection

Features:

High accuracy

Better than ±1%

Wide measuring range

Several types transducer for selection, pipe size from Dn32mm to Dn6000mm

High Reliability

Adopt low voltage, multi-pulse technology to improve accuracy, useful life and reliability.

Strong Anti-interference

Dual-balance signal differential receiver/driver circuit to avoid interference of converter,

TV tower, high voltage line etc.

Powerful Recording Function

Automatically record the following data:

1. The totalizer data of the last 512 days/128 months/10 years

2. The time and corresponding flow rate of the last 64 times of power on and off events

3. The working status of the last 32 days

Far Transmission Distance, Easy for Networking

RS485 support wireless network, connect GPRS module to accomplish wireless

transmission .

Support Heat Measurement

Connect the temperature transducer ,can finish the heat/energy measurement

Working Conditions:

| Transmitter | Transducer | |

| Protection grade | IP68 | IP68 |

| Temperature | -20~60℃ | -30~160℃ |

π type Pipe Transducer:

Threaded Connection

| Norminal Diameter(DN) | Pressure Level(P) | Length(L) | Connecting Thread | Thread Effective length | Standard |

| DN15 | 2.5 | 320 | G3/4B | 18 | GB/T7307-2001 |

| DN20 | 2.5 | 360 | G1B | 15 | |

| DN25 | 2.5 | 390 | G11/4B | 16 | |

| DN32 | 2.5 | 450 | G11/2B | 22.5 |

Flanged Connection

|

Norminal Diameter

(DN)

|

Pressure Level (P) |

Length (L)

|

Flange Dimension | Standard | ||||||

|

Outer

Diameter

D

|

Diameter of

center hole

in bolts

D1 |

Diameter of

bolt hole

×Quantity

Φ×n |

Diameter of

Sealing

surface

D2

|

Flange

thickness

|

Bolting

Specification

|

|||||

| c | f | |||||||||

|

DN

15

|

2.5 | 320 | 95 | 65 | 14×4 | 46 | 14 | 2 | M12×50 |

GB/

T9119-2000

|

|

DN

20

|

2.5 | 360 | 105 | 75 | 14×4 | 56 | 16 | 2 | M12×50 | |

|

DN

25

|

2.5 | 390 | 115 | 85 | 14×4 | 65 | 16 | 2 | M12×60 | |

|

DN

32

|

2.5 | 450 | 140 | 100 | 18×4 | 76 | 18 | 2 | M16×60 | |

Standard Pipe Transducer:

|

Norminal Diameter

(DN)

|

Pressure Level (P) |

Length

(L)

|

Flange Dimension |

Standard

|

||||||

|

Outer

Diameter

D

|

Diameter of

center hole

in bolts

D1 |

Diameter of

bolt hole

×Quantity

Φ×n |

Diameter of

Sealing

surface

D2

|

Flange

thickness

|

Bolting

Specification

|

|||||

| c | f | |||||||||

| 40 | 1.6 | 300 | 150 | 110 | 18×4 | 84 | 18 | 2 | M16×60 | GB/T9119-2010 |

| 50 | 1.6 | 300 | 165 | 125 | 18×4 | 99 | 20 | 2 | M16×70 | |

| 65 | 1.6 | 300 | 185 | 145 | 18×4 | 118 | 22 | 2 | M16×70 | |

| 80 | 1.6 | 225 | 200 | 160 | 18×8 | 132 | 20 | 2 | M16×70 | |

| 100 | 1.6 | 250 | 220 | 180 | 18×8 | 156 | 22 | 2 | M16×80 | |

| 125 | 1.6 | 275 | 250 | 210 | 18×8 | 184 | 22 | 2 | M16×80 | |

| 150 | 1.6 | 300 | 285 | 240 | 22×8 | 211 | 24 | 2 | M20×80 | |

| 200 | 1.6 | 350 | 340 | 295 | 22×12 | 266 | 26 | 2 | M20×90 | |

| 250 | 1.6 | 450 | 405 | 355 | 26×12 | 319 | 28 | 2 | M22×90 | |

| 300 | 1.6 | 500 | 460 | 410 | 26×12 | 370 | 32 | 2 | M22×90 | |

| 350 | 1.0 | 550 | 500 | 460 | 23×16 | 428 | 28 | 4 | M20×80 | |

| 400 | 1.0 | 600 | 565 | 515 | 25×16 | 482 | 30 | 4 | M22×90 | |

| 450 | 1.0 | 700 | 615 | 565 | 25×20 | 532 | 30 | 4 | M22×90 | |

| 500 | 1.0 | 800 | 670 | 620 | 25×20 | 585 | 32 | 4 | M22×90 | |

| 600 | 1.0 | 1000 | 780 | 725 | 30×20 | 685 | 36 | 5 | M27×110 | |

| 700 | 0.6 | 1100 | 860 | 810 | 25×24 | 775 | 32 | 5 | M22×90 | |

| 800 | 0.6 | 1200 | 975 | 920 | 30×24 | 880 | 32 | 5 | M27×100 | |

| 900 | 0.6 | 1300 | 1075 | 1020 | 30×24 | 980 | 34 | 5 | M27×100 | |

| 1000 | 0.6 | 1400 | 1175 | 1120 | 30×28 | 1080 | 36 | 5 | M27×110 | |

Transmitter:

Installation diagram:

DN15-DN32mm pipe segment (standard 304 stainless steel material), flange connection style (thread connection is optional)

DN32mm above pipe section style

| Accuracy | ±1% |

| Flow range | 0~±10m/s |

| Pipe Size | DN15~DN6000mm |

| Fluid temperature

|

-30~160℃ |

| Fluid types | Water, seawater, sewage, acid, alkali, alcohol, beer, various oils, etc. can conduct ultrasonic waves as a single uniform liquid |

| Piping material | Steel, stainless steel, cast iron, copper, PVC, aluminum, fiberglass and all other high quality pipes with lining are allowed |

| Outputs | 1 channel 4-20ma current output impedance 0-1k, accuracy 0.1%

1 channel OCT pulse output pulse width 6-1000ms

1 channel relay output

|

| Signal input | 3-channel 4-20ma current input, the data collector can be connected to three-wire PT100 platinum resistance to realize heat measurement |

| Communication | RS485, Modbus Protocol |

| Power supply | DC8~36V or AC10~30V AC85~264V,Equipped with waterproof power adapter |